A World of Excavation Activity Happening Below Street Level

Since excavation began eleven months ago, the focus on Phase II of the Capitol Complex Project has been moving and manipulating thousands of cubic yards of earth to reach a depth of 65 feet. The excavation has swept from west to east, starting at the 1501 Lavaca site, then 1500 Congress Avenue, and the final block of the Texas Capitol Mall. As excavation progresses, more and more earth-moving equipment has appeared on site, with the large excavators moving across the landscape like giant Tonka toys digging ever deeper.

The excavation is one of the most critical and unsung components of the Phase II project. The work is a two-pronged effort to dig to the bottom floor of the project while installing the earth retention system that will stabilize the ground for the new buildings and the surrounding area. This work will protect the building foundations and prevent water infiltration. From the street level, you can see the trucks moving on and off the site. However, the real action is happening below street level. It is only viewable from the multiple construction cameras recording the progress or if you happen to be in one of the multistory buildings adjacent to the project sites.

Utility relocation on Texas Capitol Mall site.

Planning Every Detail

Since Phase II of the Capitol Complex Project is three projects in one, planning the work sequence while gathering the manpower and equipment needed was no easy feat. The site extends over two city blocks along 15th Street, across from the State capitol. Therefore, well before any dirt was turned on the site, Construction Manager JE Dunn was busy creating a site plan to determine where the trucks would enter, load, and exit while keeping pedestrians and onsite workers safe.

The most critical step in planning the excavation was identifying any potential obstacles. The project team worked with local utility companies to relocate utilities along the streets and on the three construction sites. The 1501 Lavaca site had an overhead line that needed to be moved, and the 1500 Congress site and the final block of the Texas Mall had underground utility lines that provided service to surrounding buildings. Rerouting these lines required maintaining utility service to the buildings and supporting the City of Austin’s Streetscape program. The goal of the Streetscape program is to bury as many utility lines as possible to beautify and enhance cityscapes.

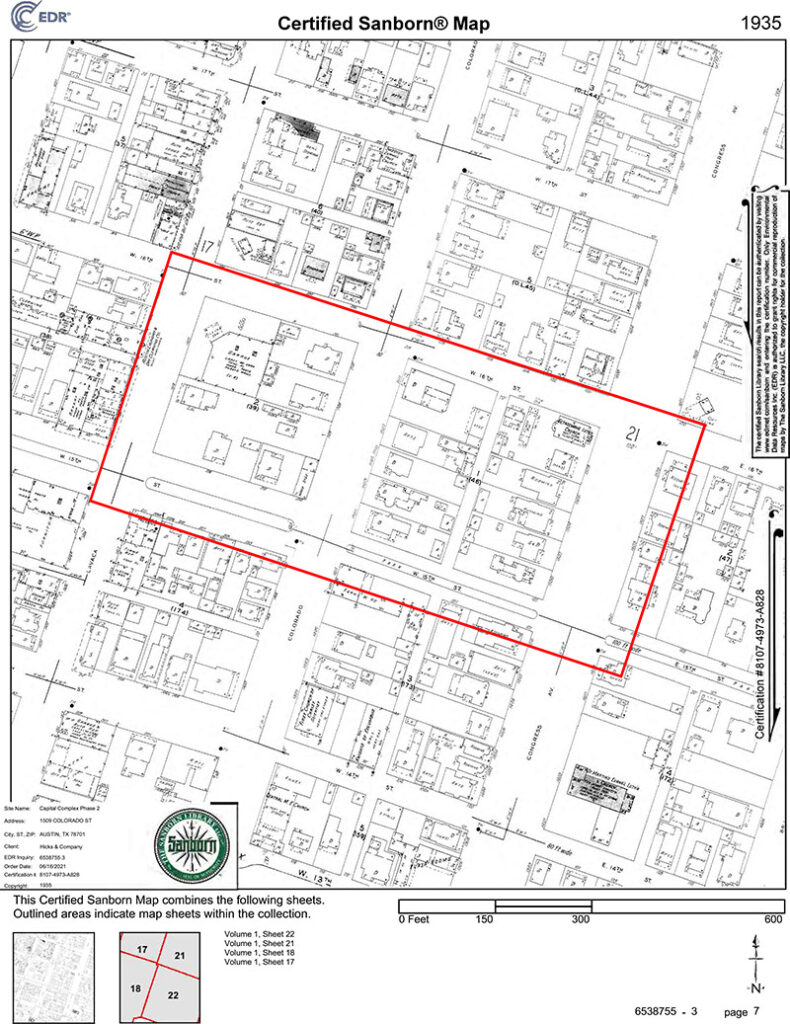

The sites have been home to several different structures throughout the years. Therefore, the team studied past archaeological studies and city records to determine if any underground obstructions might exist. The archaeological studies suggested that nothing of historical significance would be found. A City of Austin plat from 1935 showed that a filling station had once been on the 1501 Lavaca site. JE Dunn used ground-penetrating radar to verify that there were no underground storage tanks on the site. All this pre-work had to be completed before the demolition of existing buildings.

A plat record from 1935 depicts the filling station location on the 1501 Lavaca site.

Once demolition was complete, track loaders and front-end loaders with large tracks to remove pavement arrived on the sites to clear and grub the pavement and fill and reveal the limestone underneath. Then, the giant excavators moved in.

Digging 65-Feet Below Street Level

Excavation equipment moves up the earthen ramp on the Texas Capitol Mall site.

The sequence of work on the Phase II project was planned well in advance, with many meetings between team members to coordinate the workflow. The key to excavation is to begin in the middle of the site and keep the center lower than the outside. The excavation starts first, and then the installation of the earth retention system begins. As the dig progresses, the excavators form an earthen ramp that the bulldozers use to transport rock from the bottom of the dig to the trucks waiting at ground level.

“The excavation sequence is like hopscotch, alternating between the excavators and the retention,” says JE Dunn Superintendent Mike Hamline. “We plan how many trucks are needed daily and shift the work to keep the trucks rolling, equipment moving, and retention going.” The workflow also means moving the earthen ramp periodically to continue the retention and maintain the appropriate slope for the machinery. Mike compares the job site to an “amoeba,” constantly changing its shape.

The earth retention system wall looms large on the 1500 Congress site.

About thirty-five team members are working on the excavation every day. As TFC’s construction manager for the Phase II project, JE Dunn coordinates with the individual trade partners to oversee the schedule, quality, and onsite project safety. They also see the scheduling and routing of construction material deliveries to prevent impacts to the surrounding community. Construction material deliveries are coordinated with the City of Austin’s Transportation and Public Works Department to ensure that there are no impacts on City events.

“Coordinating the trucks and equipment needed for an excavation project the size of Phase II is a full-time job,” explains Mike. Several large construction projects are underway in the Austin area, so we have to understand the schedules of these other projects to ensure that the equipment we need will be available.”

A D11 bulldozer, the largest bulldozer made for non-mining construction projects, operates on the Phase II project.

Ranger Excavating, LP, the Phase II excavation trade partner, owns many of the trucks and equipment used on the project, including a D11 bulldozer, the largest non-mining bulldozer. However, the project also uses independent trucking and specialized equipment from other sources. A Ranger superintendent coordinates with JE Dunn on the number of trucks needed per day, including where the trucks will come from and the route they will take to the site. Over 23,000 loads of fill, an estimated 230,000 cubic yards, have been removed to date. The material is tested before it leaves the site and then distributed to other construction sites that need the specified fill.

Excavation during dry days means generating a lot of dust. JE Dunn has multiple trucks with high-volume blowers spraying water into the air, on the ground, and on the excavators to minimize impacts to the surrounding community.

Technology in Excavation

A prism and laser installed on a perimeter wall on Phase II of the Capitol Complex Project.

JE Dunn is also conducting 3D scanning of the excavation as the dig progresses. This process builds the as-builts, verifies that the work is done to specifications, and ensures that the building foundations will fit. 3D scanning is the first step in the total Building Information Modeling (BIM) efforts for the project and a continuation of TFC’s ongoing program to document and build a complete BIM model for all new and legacy facilities in the TFC portfolio.

A third-party consultant is monitoring the installation of the earth retention system through stations that include prism and laser sets mounted on the perimeter walls. A laser gun shoots the prisms daily to verify that there is no movement in the earth retention system. The system is accurate to within an eighth of an inch. The excavation is over sixty percent complete. Once the excavation reaches the depth of sixty-five feet, a team of geotechnical and structural engineers will verify that the excavation is done. Then, the foundation work will begin.

As the building construction rises from the ground, the excavation work will forever disappear from view. Although few people get to witness excavation, it is the essential process that creates the stability for structures to last for generations. We salute the efforts of everyone providing their expertise for this important part of the project.